Tell us about your current role with Network Architectural. How did it come to be?

I’m the Technical Manager for Facades with Network Architectural, and the way this role came about was quite interesting. Not long after I joined the company, the Grenfell Tower fire disaster occurred and the company needed someone who would have the knowledge of – or wanted to learn about – the Building Code and fire standards related to cladding. I took on the role about six years ago and have been doing it ever since.

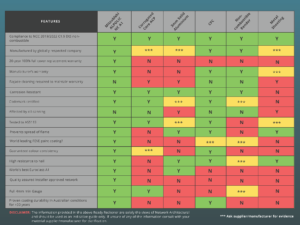

Network Architectural’s signature non-combustible product, ALPOLIC™ NC/A1, took four years to bring to life. Can you tell us what sets it apart from other products in the market?

ALPOLIC™ NC/A1 is a mineral core barrier composite panel that was initially manufactured by ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd exclusively for the Australian market to meet Australia’s strict building code requirements. Due to the success and high performance of the product, ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd then launched ALPOLIC™ NC/A1 globally and successfully tested to Euroclass A1 13501-1, the most stringent component fire test in the world.

What really sets it apart – beyond the fact that it passes all the fire tests in Australia, and is manufactured by the world leader in aluminium composite panels – is the fact that it comes with a 20-year full cover warranty backed by the globally trusted ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd. If there is a manufacturing defect in the panels, will replace it at no cost to the building owner. In my opinion, it is the most comprehensive warranty within our industry. Plus, you don’t have to wash the facade or do any maintenance to maintain the warranty.

ALPOLIC™ NC/A1 is considered to be the world’s safest aluminium facade product where fire safety is concerned. What has been the compliance journey to get the product certified in Australia?

First of all, for the compliance of a product like this with the C1.9(e)(vii) clause – commonly known as the Bonded Laminates Clause – you have to test each layer to AS 1530.1 for non-combustibility. On top of that, the adhesive layer needs to be less than two millimetres in total thickness within the panel. Our panel passes AS 1530.1. on the aluminium skins and the mineral core, and it has 0.035 millimetres of adhesive on either side of the panel. The panel is then tested to AS 1530.3., and it can’t exceed the spread flame index of more than 0, and the spread of smoke index of more than 3.

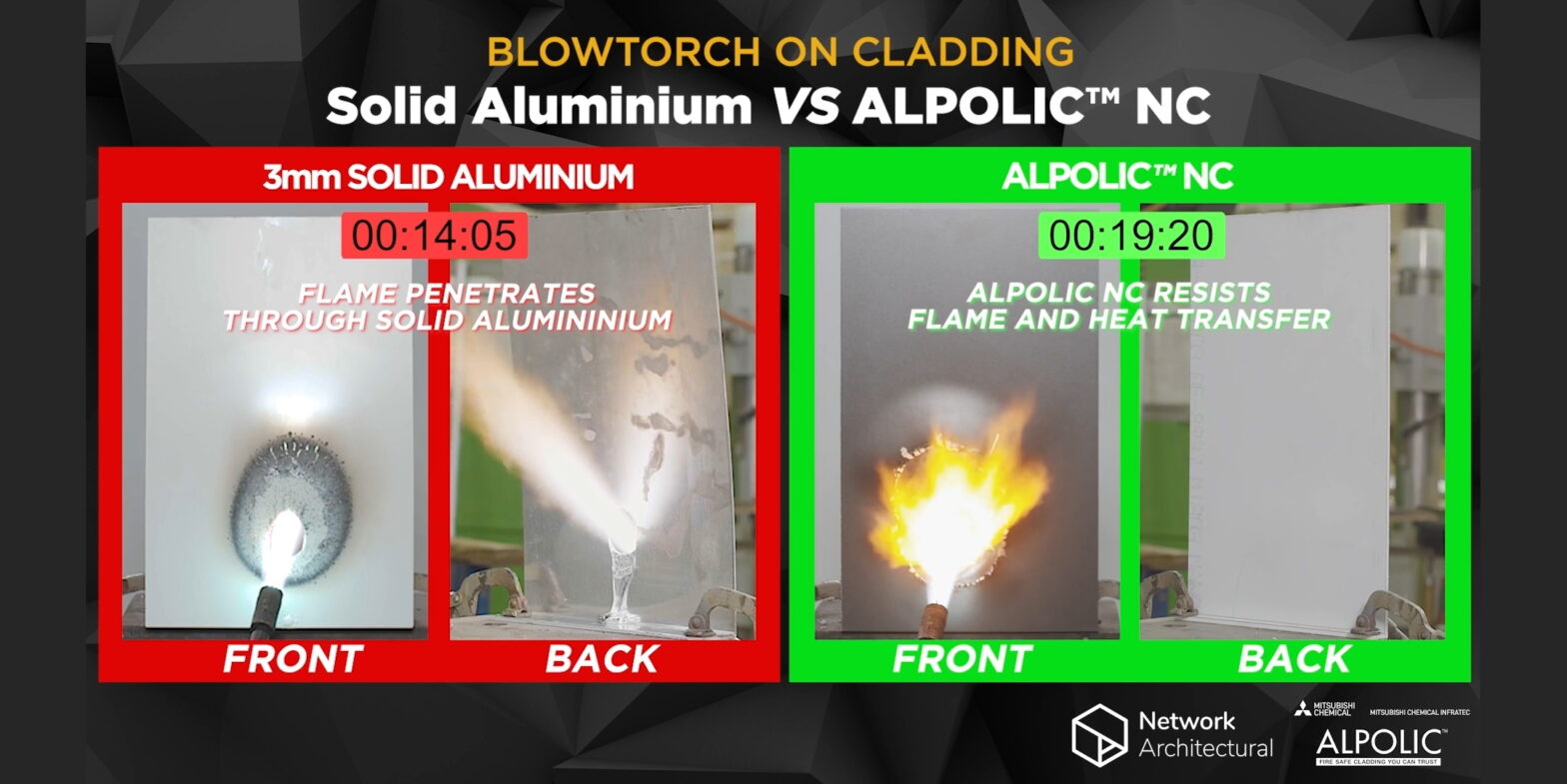

Passing these tests – and I’d consider them to be the bare minimum – means that the product can be used in applications where non-combustible materials are required, like Type A or B construction. From our perspective, we wanted to go above and beyond, so we also conducted a large-scale AS 5113 fire simulation test. The test results, by far, outperformed any other aluminium façade material in the country.

Can you talk us through the process Network Architectural and ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd went through to obtain CodeMark certification?

We successfully obtained our CodeMark certification through industry leading certification provider, SAI Global. The certificate demonstrates compliance with the Building Code through an independent assessment, which includes reviewing relevant test results as well as the audit of the ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd factory – which was organised remotely, since the panels are manufactured in Japan. It’s an incredibly extensive process, but we’re very happy to be working with SAI Global, because we’re confident that we will have a CodeMark certificate that stands up to utmost scrutiny. They really pride themselves on the work that they do.

Obtaining the Environmental Product Declaration (EPD) for the ALPOLIC™ NC/A1 was very important to Network Architectural and ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd. How long did it take and how involved was Network Architectural in the process?

It was an intense and extremely thorough process that probably took the better part of nine months to achieve. The EPD was compiled and produced by Good Environmental Choice Australia (GECA) who were very professional in the way they communicated and worked directly with ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd in Japan on cataloguing their processes and reviewing their practices. As the EPD is a product based environmental declaration, Network Architectural’s role was more to facilitate the communications between GECA in Australia and ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd in Japan.

ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd had the majority of the documentation and processes required to obtain the EPD as they already had extensive sustainability practices in place.

Let’s talk about those. ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd operates under the sustainability principles of “Kaiteki” – what do they entail?

Kaiteki is an original concept of ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd’s grounded in the notion of sustainable wellbeing of people, society and our planet with the mission to create innovative solutions, based on ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd’s core values of sustainability, health and comfort. This philosophy is reflected in the way they conduct their business. For over 20 years they have been producing fire safe products for the Australian construction market. ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd’s decision was based on safety before profit and that really encapsulates how they approach sustainability as part of their broader business ethos.

Network Architectural works closely with ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd. Is their sustainability philosophy reflected in the way your company operates?

Although we’re two separate companies, we’re extremely privileged to work with ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd so closely, and I think we often see ourselves as an extension of their business model, because we’re the exclusive distributors of their products in Australia.

And I think that – like ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd – we conduct ourselves in the most sustainable way. For instance, we recycle any material that can be recycled, we use rainwater tanks which service all the plumbing, we have solar panels which generate more than enough power for us to operate which means some of that energy is fed back into the grid. Like ALPOLIC™ by Mitsubishi Chemical Infratec Co., Ltd, we’re serious about our commitment to sustainability and it informs all facets of our business and operations.