The Sydney Metro Victoria Cross Station project in North Sydney is a striking and innovative transportation hub that seamlessly integrates functionality with urban architectural design principles. The station’s architectural design, both internally and externally, is a masterpiece that reflects the essence of modernity while paying tribute to historical elements. While completion is not due until 2024, the construction of this transportation hub is well underway. And, with durlums expertise in bespoke ceilings it has allowed us to be part of this commercial infrastructure development, along with other cross city railway stations. Part of the design process of this precinct was to ensure “a customer centred design approach that placed customer experience at the centre of every design decision.” (Station Design & Precinct Plan), which is the exact approach durlum takes to designing commercial ceiling systems – always with the customer in mind.

So, when it came to the Victoria Cross Metro Station the brief was to bring the Architects design to life in both the north and south entrances. This involved creating mesmerising bespoke ceiling engineered and designed for practicality in any busy railway station. For Network Architectural and durlum our expertise and thorough bespoke ceiling design process were key aspects that lead to the appointment of working on such a large scale, forward-thinking public transportation project.

Bespoke metal ceiling design process

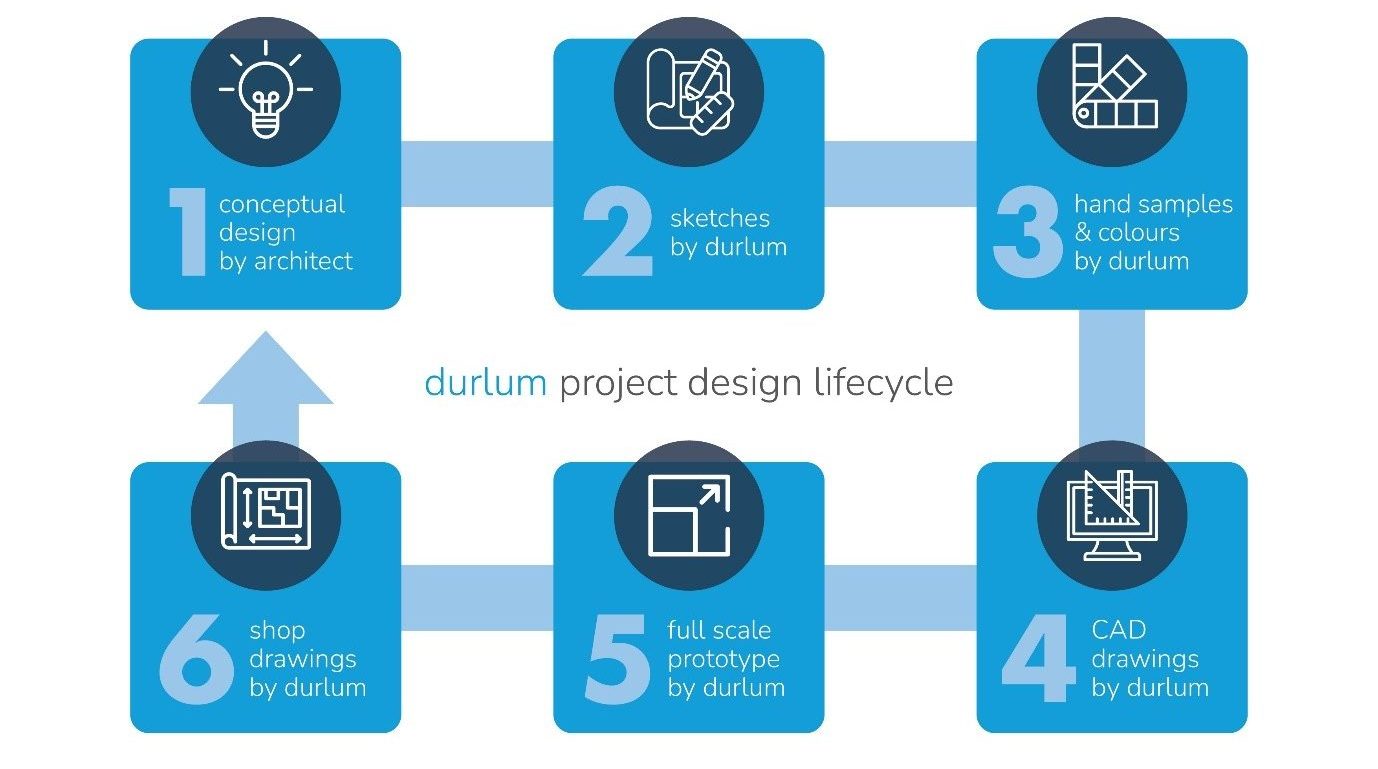

At Network Architectural our durlum Project Design Lifecycle is one value-add that really sets us apart, “our collaborative approach means we engage with the various stakeholders throughout the project lifecycle; from conceptual design right through to installation”, says Paul Sheehan, Ceiling Systems Manager, this enables design flexibility and ease of implementation in such a large scale commercial project.

For Network Architectural and the durlum design team there is no better feeling than bringing an architects bespoke ceiling design to life, while making the design process as “customer centred” as possible, a lot like the Sydney Metro Victoria Cross Station Precinct itself.

|

|

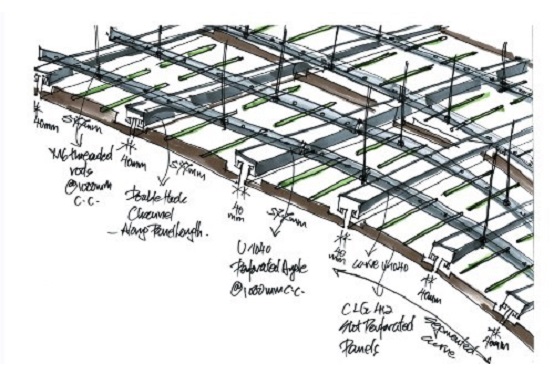

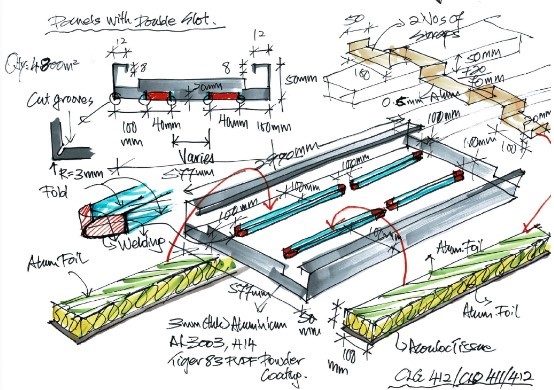

In the case of this bespoke ceiling project it all started with taking COX Architecture’s vision for the transport hub and crafting it into a 3D hand drawn sketch by our design team. The importance of this step is that it creates a clearer picture for the key stakeholders to better showcase the concept at a glance. “We often find at times conventional CAD drawings in 2D can miss out certain layering details without magnifying the drawings, sketching the concept as a first step, often saves time on any misunderstanding on the concept early on in the process” says SY Chan, Area Sales Manager South-East Asia, durlum. Our team of experts have a good understanding of both production and installation that ensures a very thorough design sketch. To further ensure greater accuracy in the design, hand samples with colour matching were also supplied – so the exact colour and product was clear from the onset.

|

|

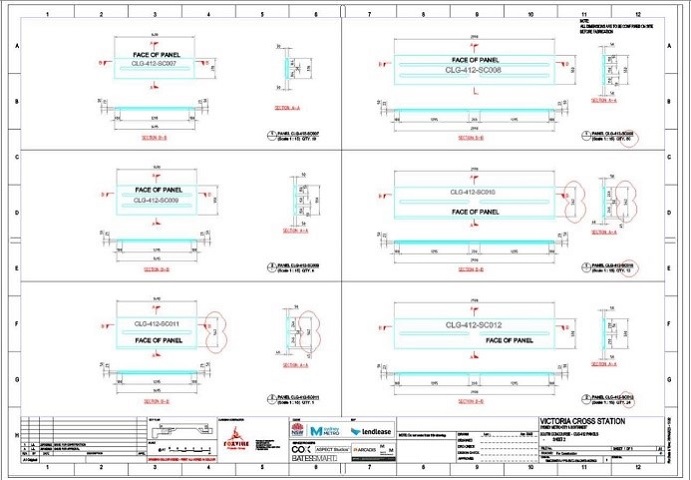

Once the sketches were approved, detailed CAD drawings were produced by durlum. “It was the detail in the sketches that ensured the accuracy of the CAD drawings and that no technical detail was missed” says SY Chan, Area Sales Manager South-East Asia, durlum. Full scale prototypes were then created to ensure everything was correct and nothing was missed for the installation of such a detailed architectural ceiling system.

|  |

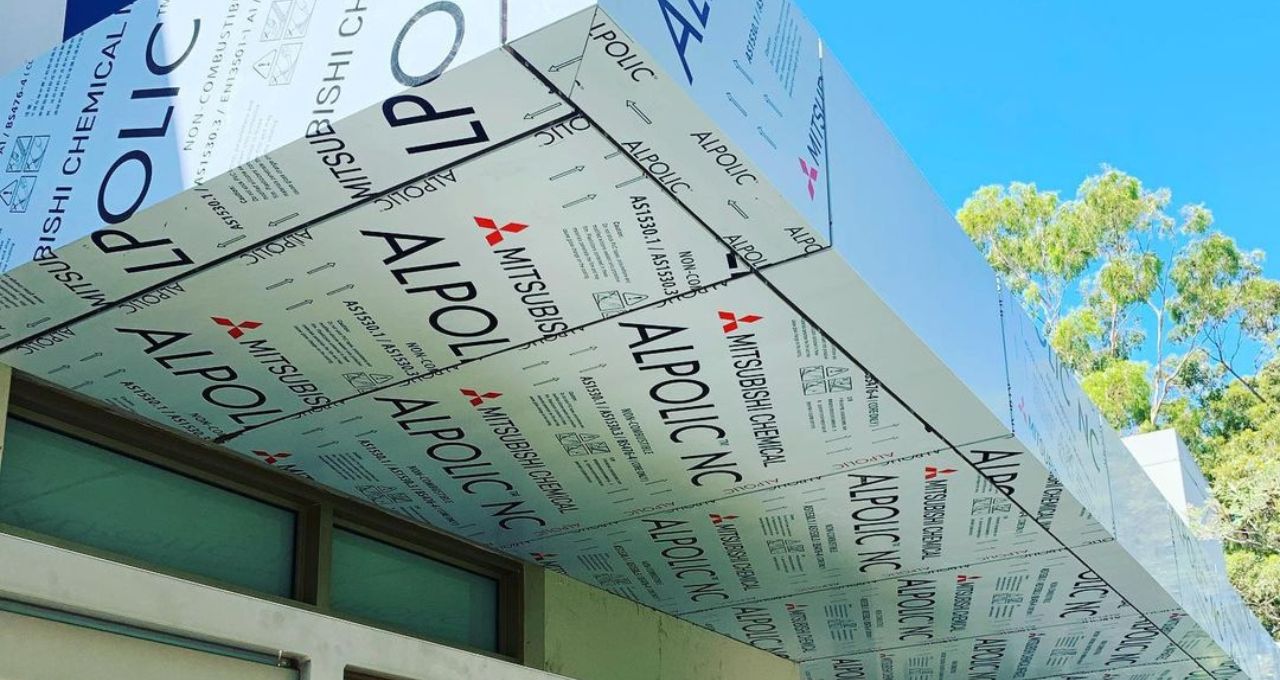

durlum ceilings system

For the Sydney Metro Victoria Cross Station, durlum’s S7 metal ceiling system was chosen and modified to suit the custom design requirements. Our design also included the incorporation of perforated service channels to accommodate the various required services such as lighting, speakers and sprinklers, while still meeting the ceiling acoustic properties for the overall design. This precisely engineered grid design allowed it to conceal these services, creating a seamless integration. Our unique locking bracket allows the bespoke ceiling system panels to hold securely in place, while making it easily accessible and removable for future maintenance purposes.

durlums meticulous detailed design process ensured the best ceiling system design was created to complement the contemporary aesthetic of the Victoria Cross Metro station, while allowing functionality for all services and future maintenance requirements. Ultimately it has also meant that significant time has been saved due to the ease of the installation. We look forward to sharing the progress and end result of the Victoria Cross Metro Station project once completed (scheduled for 2024).

| |

|

|

At Network Architectural as experts in transport infrastructure we deliver innovative and high-quality ceiling solutions to commercial clients in Australia and around the world. We understand the importance of customised design to meet specific interior purposes, be it acoustic regulation, integrated lighting or as a seismic solution. Our detailed design process and expert architectural team, as showcased in this project, allows an efficient and seamless integration from concept to installation no matter how complex the project. Contact us today to discuss your next bespoke ceiling project.

Hail damage Brisbane CBD, QLD

Hail damage Brisbane CBD, QLD Hail damage Newcastle, NSW (Photo credit: ACLAD)

Hail damage Newcastle, NSW (Photo credit: ACLAD)