Specifying sustainable aluminium: Understanding the real environmental footprint of façade materials with LCA

Life Cycle Assessment (LCA) is fast becoming a must-have for architects navigating embodied carbon caps and stricter procurement standards. Yet, not all aluminium cladding is created equal. In this article, we break down how LCA helps specifiers cut through assumptions, compare Environmental Product Declarations (EPDs), and make sustainable, evidence-based design choices with confidence.

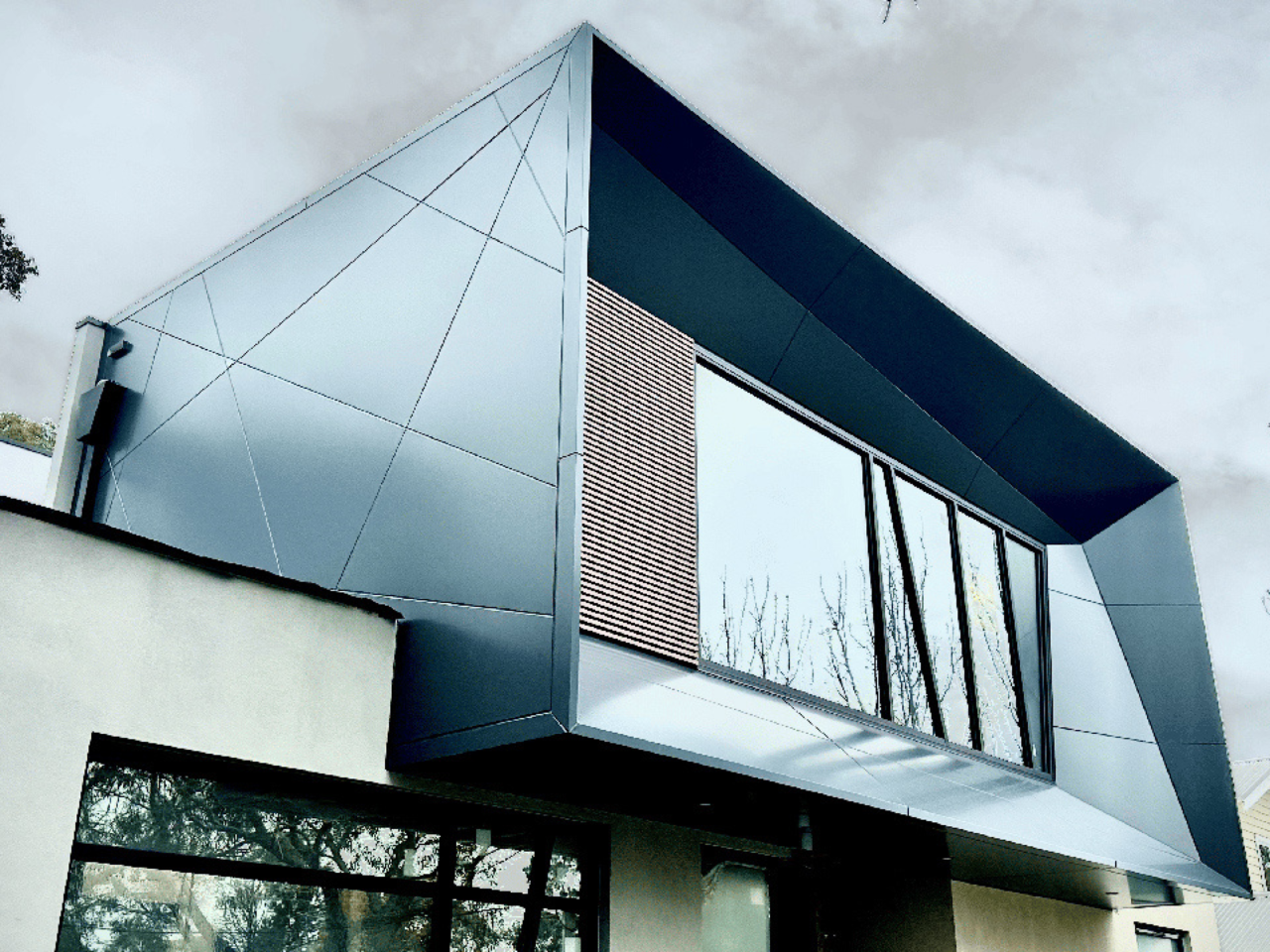

Fraternity Club, Wollongong NSW

The concept of Life Cycle Assessment (LCA) is by no means new. However, while in many instances it remains in the “nice-to-have” category, Llewellyn Regler, Network Architectural’s National Technical Manager, predicts a shift. “In the next 5-10 years, we expect LCA to move to a compliance necessity, especially as embodied carbon caps and government procurement standards tighten,” he explains.

However, despite LCA’s undeniable importance, a substantial gap between principle and practice can significantly hinder the sustainable specification of building materials, such as aluminium cladding.

Same but different: The aluminium assumption

“One of the biggest misunderstandings we encounter is the assumption that all aluminium products have roughly the same environmental profile,” explains Llewellyn, who earlier this year ran an in-depth CPD course on the topic. “In reality, there are vast differences depending on factors like core composition, coating technology and end-of-life recyclability.”

Understanding LCA is essential to deciphering these differences. To help architects distinguish between sustainable products and those that merely claim to be so, we asked Llewellyn to demystify the methodology and outline how to turn complex data into a powerful design tool that satisfies the demands for environmental accountability, including those outlined in the National Standard of Competency for Architects 2021.

Scarboro Toyota, Osbourne Park NSW

What is LCA?

At its core, LCA is a systematic analysis of the environmental impacts of a product across its entire lifecycle. To properly assess a product, an LCA is conducted using specialised software according to standards like ISO 14040 and ISO 14044 to examine everything from raw material extraction to disposal, including manufacturing processes, energy consumption and the material’s recyclability. It also considers factors ranging from long-term life expectancy and maintenance requirements to the depletion of fossil fuels, offering a nuanced and comprehensive view of a product’s lifecycle impacts.

Decoding LCA’s vernacular

To understand this intricate data and avoid the common specification misunderstandings, it’s essential to grasp LCA’s vernacular, starting with cradle-to-gate and cradle-to-cradle.

In simple terms, cradle-to-gate refers to the first part of the lifecycle, encompassing the impacts of raw material extraction, transportation and manufacturing – everything required to prepare a product for shipment from the factory. While it’s a vital metric covering the A1-A3 stage, it’s not the whole picture. Cradle-to-cradle, on the other hand, represents the complete, holistic view that architects should strive for. It assesses the entire lifecycle, including the use phase, end-of-life processing and the potential for the material to be reused or recycled into new products, closing the loop.

Being able to differentiate between the two, Llewellyn stresses, is essential. “A key knowledge gap lies in differentiating between embodied carbon at early stages (A1-A3) versus operational impacts and end-of-life scenarios,” he elaborates.

Lake Road, Blackburn VIC

The stages of LCA

LCA enables industry professionals to bridge that gap, providing essential data about a product’s impact across the critical lifecycle stages that answer fundamental questions about the material or product in question.

Product Stage (A1-A3): Where does it come from and how is it made? Includes raw material supply, transportation, and manufacturing.

Construction Stage (A4-A5): How does it become part of the building? Encompasses the transport of the finished product to the site and the installation process.

Use Stage (B1-B7): How does it live in the building? Covers long-term maintenance, repair, and replacement needs, plus operational energy and water use.

End of Life Stage (C1-C4): Where does it go when it’s done? Includes deconstruction, transport from the site, waste processing, and final disposal.

Benefits Beyond Stage (D): What is its next life? Accounts for the future benefits of reuse, recovery and recycling, linking directly to the circular economy.

Recladding – Sandpiper Building, QLD

From energy-intensive Stage A1…

Understanding the impact of each stage – and giving it appropriate weighting – is paramount. Llewellyn explains that Stage A1 is often the most significant contributor to environmental impact due to energy-intensive mining and refining processes, particularly with virgin aluminium.

Understandably, architects usually focus on this stage the most. However, he notes that it’s the frequently overlooked end-of-life stage that presents significant challenges and opportunities.

… to the underestimated Stage C

“Stage C is often underestimated,” Llewellyn explains. “Many assume materials are recycled or disposed of responsibly without truly understanding the environmental cost or practicality of doing so.”

While aluminium itself is infinitely recyclable, using just 5% of the energy required for primary production, complexity arises with aluminium composite panels (ACPs), where the core materials may not be recyclable.

Network Architectural, an Australian distributor of the advanced ACP ALPOLIC™ panels, for instance, address this consideration head-on. The company’s take-back partnership with PanelCycle creates a verified pathway for recycling the panels, ensuring that the aluminium skins and mineral cores are properly separated and recovered, turning a theoretical recycling claim into a tangible reality that can be verified through the product’s EPD.

And that, Llewellyn adds, is the key. “The actual recyclability depends on product design, which is why we recommend project teams request EPDs that include complete Stage C and interrogate manufacturers’ claims regarding recyclability and landfill,” he explains, stressing the importance of challenging suppliers to translate abstract figures into practical, project-specific terms.

City Toyota, Nedlands WA

Integrating LCA into the design workflow

With that in mind, when is the best time to integrate this holistic methodology into the design process to maximise its potential for a project’s sustainability profile?

“The best time to apply LCA thinking is during schematic design when material decisions are still flexible and cost modelling is underway,” Llewellyn explains, adding that embedding it into early-stage concept presentations and specification checklists can help it become second nature. “It has to become a non-negotiable part of the workflow.”

To start, he suggests that specifiers should shortlist products with third-party verified EPDs – ideally EN 15804-compliant and from trusted program operators, such as Australasia EPD or Global GreenTag. Doing that helps avoid greenwashing, mitigates the risks of internal, unverified LCAs – plus, specifying products with verified EPDs can directly contribute to earning points in rating schemes like the Green Building Council of Australia’s (GBCA) Green Star.

Once shortlisted, Llewellyn recommends comparing each EPD’s most crucial data points. In addition to the Stage C data he’s mentioned, he highlights a few other points architects and designers should pay attention to ensure sustainable aluminium cladding specification:

- Global Warming Potential (GWP): The primary carbon footprint metric.

- Recycled vs. Virgin Content: A key indicator of upfront embodied carbon.

- Durability and Maintenance (Stage B): Indicators of how long the product will last and what the environmental cost of its upkeep is.

Putting theory to the test: An LCA case study of aluminium cladding

Now, the transformative potential of EPD-backed data comes to the fore when specifying aluminium cladding. The material is energy-intensive to produce but can be highly durable and recyclable – and the physical construction of different cladding types directly impacts their environmental footprint.

With various aluminium cladding options available on the market – including older-style solid aluminium, modern ACPs like the non-combustible mineral core ALPOLIC™ NC/A1 and lighter-weight but less durable corrugated and honeycomb panels – LCA becomes essential.

Recladding – Sandpiper Building, QLD

Not all aluminium cladding is environmentally equal

An EPD-based comparison for 1m² of different cladding types reveals significant differences. To start with, ALPOLIC™ NC/A1 has a GWP of 48.9 kg CO₂e, which is significantly lower than a typical 3mm solid aluminium cladding at 86.8 kg CO₂e and a generic composite panel with no recycled content at 95.2 kg CO₂e.

“Solid aluminium generally has a higher GWP due to its significantly greater mass per m² and the energy required to produce virgin aluminium,” Llewellyn explains. “And this is especially important in cladding, where the surface area is vast and minor improvements in GWP per m² can scale up quickly.”

This performance gap widens during the use stage. A typical 3mm solid aluminium panel uses a PVDF paint coating and requires periodic cleaning to maintain its 15-year conditional warranty. It is also prone to oil canning – visible distortion from thermal expansion and contraction – and can suffer from inconsistent colour between panels, even those from the same batch. In contrast, ALPOLIC™ NC/A1 features a superior Lumiflon FEVE paint coating, which has a life expectancy of over 50 years and is guaranteed not to fade. “ALPOLIC NC’s 20-year maintenance-free warranty can help reduce impact during Stage B,” Llewellyn says. “Which often gets overlooked in specifications.”

And while both ALPOLIC™ NC/A1 and solid aluminium are recyclable, the solid aluminium panels’ higher mass per m² leads to greater energy use in processing. “As a result, ALPOLIC™ NC/A1 offers a lower overall environmental burden at end-of-life, thanks to its efficient material use and design for recyclability,” Llewellyn explains, highlighting ALPOLIC™ NC/A1’s stronger performance in Stage C.

From theory to reality: A Sydney project transformation

A recent commercial project provides a real-life context for this data-driven comparison – and highlights the importance of employing LCA thinking early in the process.

“The project team initially specified 3mm solid aluminium cladding. However, after reviewing independently verified EPDs and assessing the embodied carbon impact across the façade, the team switched to ALPOLIC™ NC/A1,” Llewellyn describes. “The outcome was significant – a 38% reduction in GWP across the façade.”

He adds that, beyond the environmental gain, the switch also delivered practical benefits. “ALPOLIC NC/A1’s lighter construction and greater dimensional stability meant faster installation and reduced engineering complexity, particularly important given that solid aluminium is more prone to oil canning and often requires additional stiffeners and a heavier gauge frame.”

Plus, the ongoing maintenance and cleaning costs were significantly reduced, positioning this project as a powerful example of how sustainability, performance and cost efficiency can successfully align when decisions are informed by precise, comprehensive and verified data.

Golden Blade Barbershop, QLD

The future is measured

This holistic, data-driven approach genuinely empowers architects to master the complex balancing act of weighing critical environmental outcomes against functionality, design versatility and lifecycle costs. And, as Llewellyn points to a deeper integration of LCA with BIM, which will enable real-time assessments during the design phase in the next few years, the message is clear – the time to build LCA expertise is now. And Network Architectural is ready to help navigate this transition.

“We’re committed to staying ahead by providing not just compliant products, but education and support that empowers better decision-making,” Llewellyn concludes. “From CPDs to 1:1 spec support and transparent EPDs, we want to make sustainability practical. Our role is to simplify the complexity of LCA so that architects can specify with confidence, knowing the material they choose aligns with both performance and planetary responsibility.”

Related Articles

Recladding with Confidence: How the University of Sydney Delivered a Future Proof Façade

When the University of Sydney reclad the Charles Perkins Centre, compliance alone was not enough. This article explores how a premium, maintenance-free façade solution delivered long-term confidence, design integrity and fire compliance, restoring one of the campus’s most recognisable buildings with a future-proof architectural outcome.

Top 5 Residential Facade Trends in 2026 – and How ALPOLIC™ Brings Them to Life

Australian residential facades are evolving, with 2026 trends favouring clean lines, layered materials, natural finishes and bold colour accents. This article explores the top five residential façade trends shaping contemporary homes and how material choice plays a key role in balancing design expression, durability, sustainability and long-term performance.

How ALPOLIC™ Became the National Standard for Toyota Dealerships

Toyota’s nationwide brand consistency relies on materials that look flawless, perform reliably and meet strict compliance standards. This article explores why ALPOLIC™ has been Toyota’s trusted façade and signage solution for more than two decades, and how its durability, colour stability and technical support have cemented it as the national standard across TMCA dealerships.