Recladding for Safety and Style: ALPOLIC™ NC/A1 Transforms Top Ryde Residential Tower

When fire safety compliance prompted the recladding of multiple residential towers at Top Ryde, ALPOLIC™ NC/A1 was chosen for its DtS non-combustibility, seamless colour matching, and long-term durability. Backed by Network Architectural’s expert support, the result is a safe, striking façade upgrade that delivered on performance, aesthetics, and peace of mind.

Non-combustible mineral core aluminium cladding delivers compliance, confidence and seamless colour matching at scale

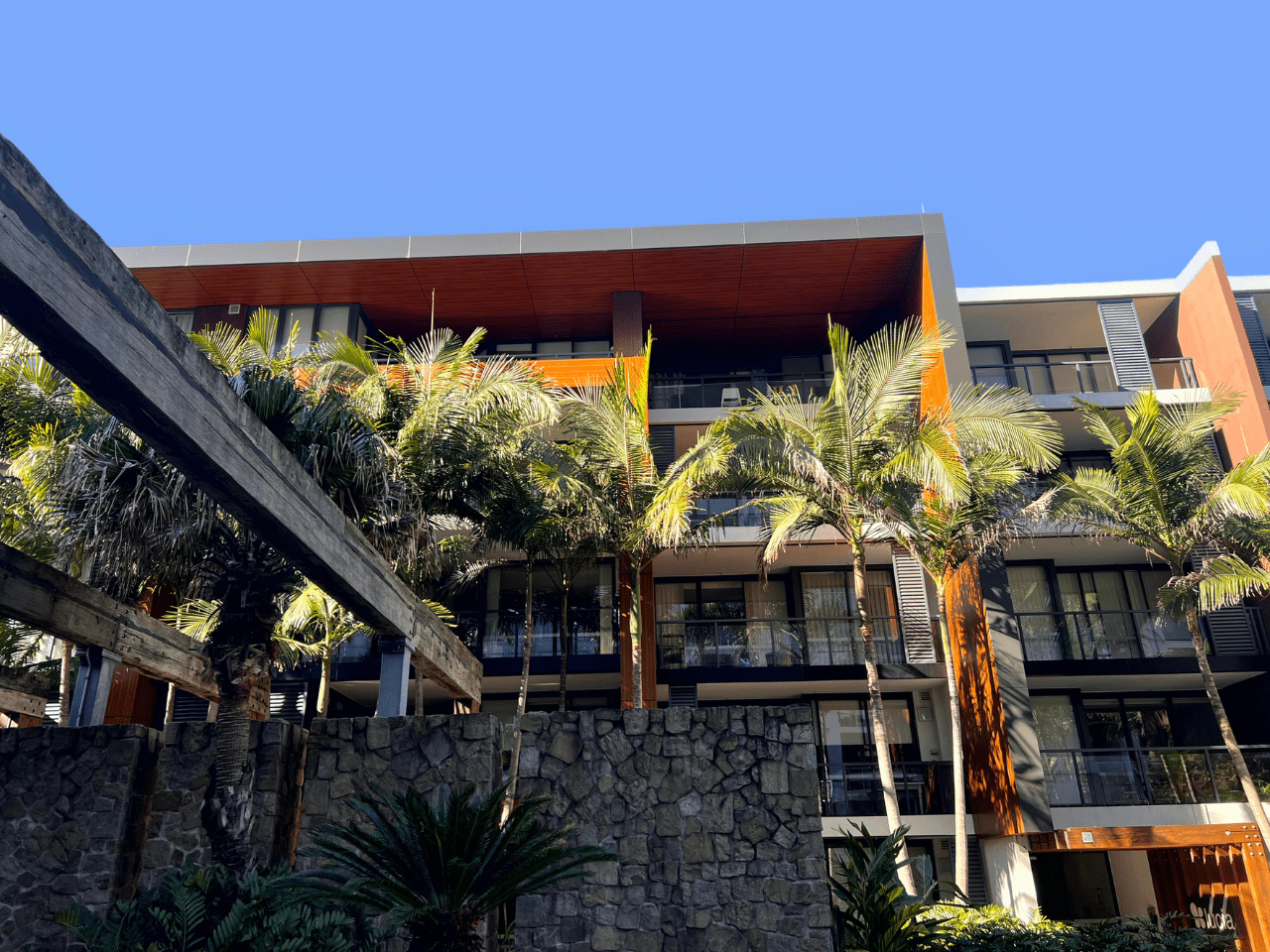

When the residential apartment buildings above Top Ryde City Shopping Centre were issued a fire order to replace all non-compliant cladding, it set in motion a carefully managed recladding project that would need to balance aesthetic continuity with compliant safety standards.

The brief was clear: remove all combustible cladding materials and replace them with a compliant solution that would meet the strict requirements of the NCC 2019 and deliver a long-term, low-maintenance result. But with multiple buildings and finishes across the site, the complexity of the recladding job was far from simple.

When it came time to address the fire order, Diagnostech brought their trusted expertise to the table, working alongside Network Architectural—the exclusive distributor of ALPOLIC™ NC/A1, a non-combustible mineral core aluminium cladding solution designed for superior performance and compliance.

Diagnostech, who led the diagnostics and specification phase, explained the urgency of the project:

“The building was issued with a fire order requiring the removal of all non-compliant combustible cladding. Our role was to ensure that the replacement not only achieved compliance but would future proof the building against further risks.”

The team selected ALPOLIC™ NC, a non-combustible mineral core composite panel that meets the fire compliance requirements of AS 1530.1 and is compliant under NCC 2019 Deemed-to-Satisfy provisions.

“We specifically chose ALPOLIC™ NC over solid aluminium due to its superior flatness and reduced risk of oil canning,” Tom Mackay, Director from Diagnostech. “It allowed us to maintain the building’s original look without compromising fire safety or design intent.”

The technical complexity of the job was no small feat. With multiple towers in varying colour palettes and cladding configurations, ensuring a smooth transition and same aesthetics was essential.

Llewellyn Regler, Technical Manager at Network Architectural, worked closely with all project partners throughout the recladding process.

“This project involved replacing around 6,500sqm of cladding across a number of connected residential towers. Each building had different finishes and colours, and our ability to match those existing colours precisely with ALPOLIC™ NC was a major advantage,” he said.

“From a compliance and visual perspective, the result is exceptional. The panels look sharp and clean, and everyone—from the client to the consultants—was really happy with the outcome.”

Certified Safety and Superior Façade Finish

ALPOLIC™ NC/A1 is manufactured in Japan by Mitsubishi Chemical Infratec Co., Ltd and is a next-generation cladding material that combines the lightweight benefits of composite panels with DtS non-combustibility, exceptional flatness, and a high-performance Lumiflon™ FEVE paint system that comes with a 20-year full cover warranty.

“We were particularly drawn to the strong warranty provisions, which include cover for material, labour and rectification costs,” said Diagnostech. “That level of assurance is above industry standard, and gave the client added peace of mind.” ALPOLIC™ does not require any ongoing maintenance in order to maintain the warranty, which represents a significant cost saving to the building owner.

The product’s durability and low-maintenance finish were further deciding factors in its selection.

“This project demanded a long-term solution. ALPOLIC™ NC delivers just that—robust performance, minimal maintenance, and a finish that lasts.”

One of the key challenges in the project was material availability and cost control.

“Procurement was a concern—especially with price escalations occurring across the market,” said Diagnostech. “We were able to work collaboratively with the builder and Network Architectural to pre-order the panels at a locked-in price, ensuring materials were delivered on time and within budget. That coordination was invaluable.”

Network Architectural’s full-service support was a key part of the project’s success.

“From initial consultation to final delivery, their service was professional, responsive and solution-oriented,” Diagnostech noted.

For Network Architectural, supporting clients through the recladding process is about more than just supplying compliant materials—it’s about providing clarity, guidance and a proven process from start to finish.

“We work closely with consultants, builders, fabricators and clients to ensure everything is compliant, coordinated and clear,” said Llewellyn. “That’s especially important in recladding projects where there’s a lot of pressure to deliver safely, quickly and within the rules.”

For the Top Ryde residential towers, the completed project is a case study in how recladding can be done right—with no aesthetic compromise, no compliance concerns, and no delays.

“The clean finish, colour consistency and sharp detailing really elevate the building while preserving its original identity,” said Diagnostech. “It’s a true example of how non-combustible mineral core aluminium cladding like ALPOLIC™ NC can deliver both form and function.”

“We would confidently use Network Architectural’s products again and recommend them to others in the industry.”

ALPOLIC™ NC/A1 is a non-combustible mineral core aluminium composite panel that meets the highest global fire safety standards, including AS 1530.1 and Euroclass A1 classification as defined by EN 13501-1. It combines advanced fire resistance with design flexibility, flatness and durability. Manufactured in Japan by Mitsubishi Chemical Infratec Co., Ltd and exclusively distributed in Australia and New Zealand by Network Architectural, ALPOLIC™ NC is the premium choice for recladding and façade projects requiring absolute compliance.

Network Architectural offers a complete façade solution—from product supply to compliance documentation, colour matching, and technical support. With decades of industry experience we help architects, builders and consultants deliver safe, striking and compliant buildings, every time. For more information or help with your next project contact us today.

Related Articles

Recladding with Confidence: How the University of Sydney Delivered a Future Proof Façade

When the University of Sydney reclad the Charles Perkins Centre, compliance alone was not enough. This article explores how a premium, maintenance-free façade solution delivered long-term confidence, design integrity and fire compliance, restoring one of the campus’s most recognisable buildings with a future-proof architectural outcome.

Top 5 Residential Facade Trends in 2026 – and How ALPOLIC™ Brings Them to Life

Australian residential facades are evolving, with 2026 trends favouring clean lines, layered materials, natural finishes and bold colour accents. This article explores the top five residential façade trends shaping contemporary homes and how material choice plays a key role in balancing design expression, durability, sustainability and long-term performance.

How ALPOLIC™ Became the National Standard for Toyota Dealerships

Toyota’s nationwide brand consistency relies on materials that look flawless, perform reliably and meet strict compliance standards. This article explores why ALPOLIC™ has been Toyota’s trusted façade and signage solution for more than two decades, and how its durability, colour stability and technical support have cemented it as the national standard across TMCA dealerships.